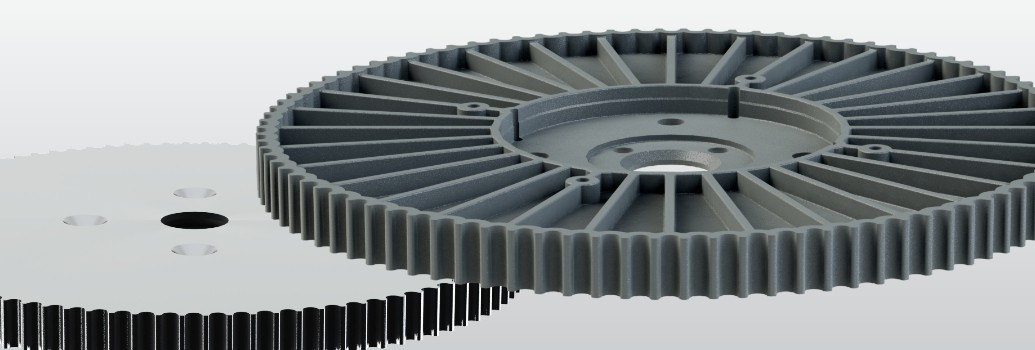

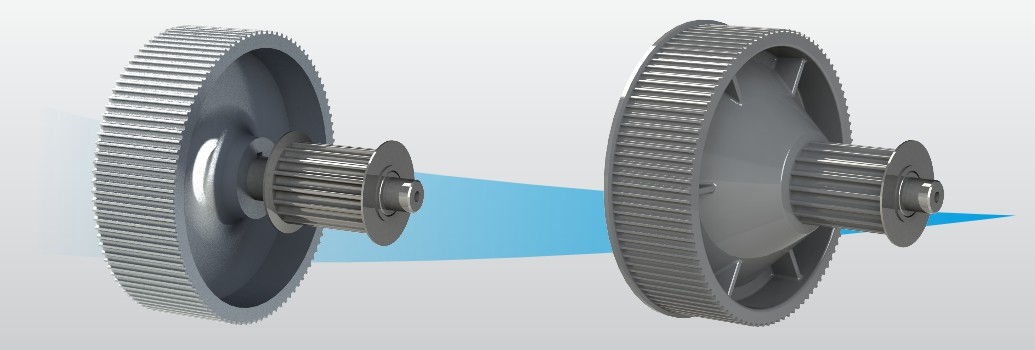

These projects are a good example of successful "Value Engineering." Many gears and poulies are produced by machining. The great advantage is the high dimensional accuracy of the parts. But at the same time, it is a disadvantage of the relatively high cost of machining. Economically, casting an interesting technique that can significantly reduce the product cost. But it requires knowledge and experience to successfully produce such parts by injection molding.

What has Rokatec done?

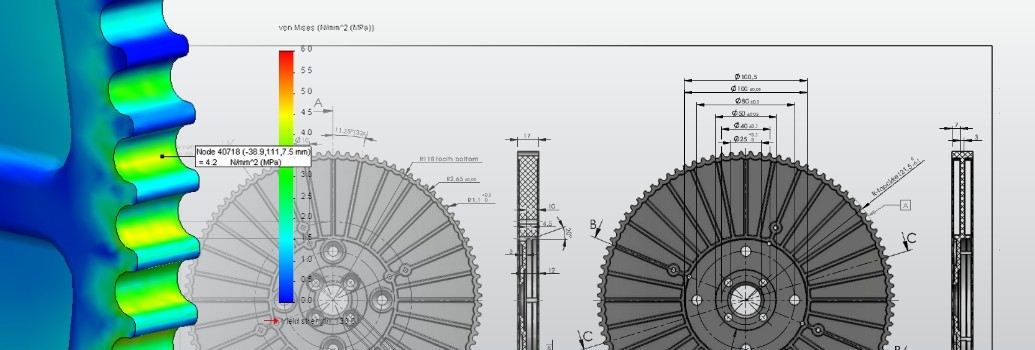

Rokatec has performed a material research to find out the optimum material. In addition, the geometry is optimized specific for the injection molding process. An important part of the design has been the strength analysis. Because the parts are made in a weaker material, this analysis is of major importance. Through the selection of the right material, the correct geometry and by integrating multiple components is a cost saving of 55% achieved.