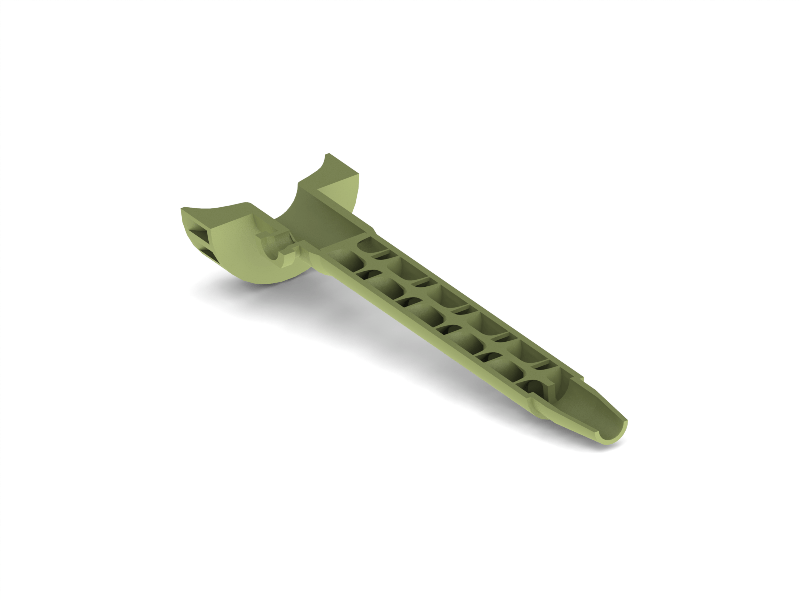

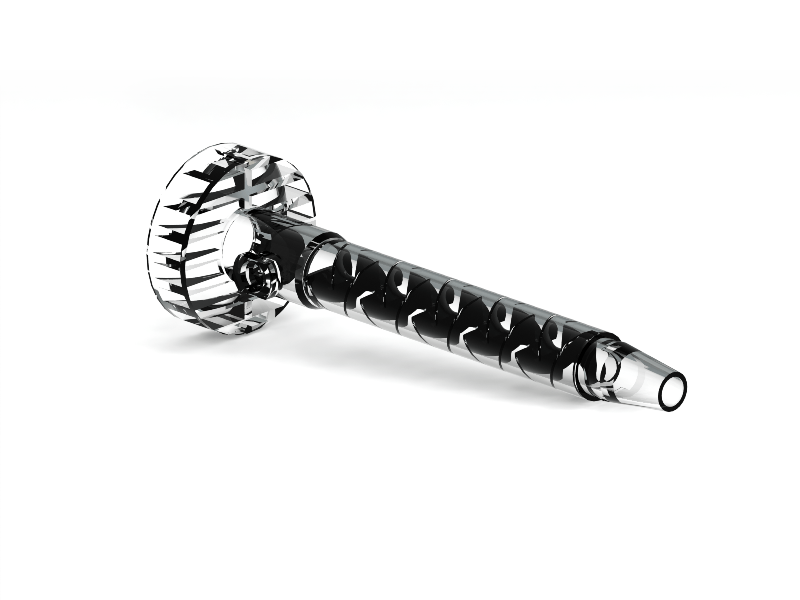

A new static mixer is developed to improve the functionality of the pneumatic sealant gun. This mixer realise the same mixing quality of the glue with a lower pressure. The complicated shape of the mixer is created as one single part with the famous SLS 3D printing technique.

Aanzienlijke besparingen

The lower strength of the sintered nylon powder compared with the final intended material has been compensated due to the single body of the mixer and the nozzle. In that way many different prototypes can be tested in short time . Both the lead time and the investments costs are significant reduced without reducing the final quality. The production of the tool of the optimal shape of the mixer is released now.